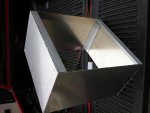

Whew! After a solid week of work my totally scratch built 150A distro is complete. I did all the metalwork and built the enclosure. The enclosure is made from 2 2x4' sheets of 3/16" aluminum plate, all assembled with rivets and stainless steel hardware. The hardest part was all of the cut outs for the breakers. I had to cut the slots with a jig saw and then use a router and template to shave the final 1/32" off and give it a nice clean edge. The cutouts came out perfect and the whole panel looks CNC quality, I'm pretty pleased.

It's all mounted completely free floating and shock mounted in a "pocket door" style rack that matches all of my "A-rig" amp racks, so the setup is very clean. LED rope light to help making connections easier.

Electrically it has 6 L21-30 and 2 L5-20 outlets for amp racks, 1 dedicated L21-30 for my FOH power run, and 3 20a Edison circuits for utility and backline power. There is a meter that shows voltage, current, and power factor on all 3 legs. Cam lock input with a 150A main breaker.

It's all mounted completely free floating and shock mounted in a "pocket door" style rack that matches all of my "A-rig" amp racks, so the setup is very clean. LED rope light to help making connections easier.

Electrically it has 6 L21-30 and 2 L5-20 outlets for amp racks, 1 dedicated L21-30 for my FOH power run, and 3 20a Edison circuits for utility and backline power. There is a meter that shows voltage, current, and power factor on all 3 legs. Cam lock input with a 150A main breaker.