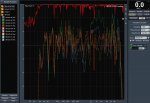

So we bought some EAW SM122's last year. And they weren't in the best shape. I've been into all of them cleaning out some very dirty HF coil slots, replacing a diaphram or two and one HF magnet assembly as the phase plug had the center portion missing. Still after all the work and fresh parts they have problems. Here's SMAART traces of all 4 with nothing but HPF applied.

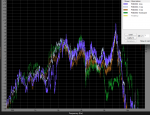

As you can see they very but the purple trace (#4) is very different.

Since I've been inside them all and checked for aftermarket and rubbing drivers and can eliminate that as an issue I can only think of the passive crossovers as the problem.

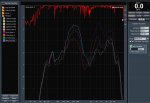

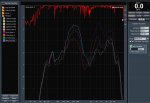

They have a interesting passive crossover network with a midrange control that goes from -6 to +3. These controls in there current condition don't appear to work except when you turn them past 0 to the (+) side of things then you get the mid range boost to engage but only at one level. Not variable as you turn the knob. On a few of the wedges you need set this control to engage the boost to get the wedge to behave appropriately and on a few you need to have it off to get them close to parity.

What should I look at on the crossover networks to get these to behave? Caps? The first three I can live with as the sonic differences aren't that great but #4 sounds obviously different. I have a note on the worst wedge itself as to how to bring it back to earth with graphic EQ settings but this is not how I like to roll.

I don't mind digging into them to replace parts on the crossover PCB's but I need to know what's going to help and what's wasting time. I've already wasted enough time on these.

Thanks guys.

Edit: I should add that it's not possible to just bypass the crossovers and bi-amp as we don't have the amp channels and NL4 and buying such would be more expensive then just selling them off for something else.

As you can see they very but the purple trace (#4) is very different.

Since I've been inside them all and checked for aftermarket and rubbing drivers and can eliminate that as an issue I can only think of the passive crossovers as the problem.

They have a interesting passive crossover network with a midrange control that goes from -6 to +3. These controls in there current condition don't appear to work except when you turn them past 0 to the (+) side of things then you get the mid range boost to engage but only at one level. Not variable as you turn the knob. On a few of the wedges you need set this control to engage the boost to get the wedge to behave appropriately and on a few you need to have it off to get them close to parity.

What should I look at on the crossover networks to get these to behave? Caps? The first three I can live with as the sonic differences aren't that great but #4 sounds obviously different. I have a note on the worst wedge itself as to how to bring it back to earth with graphic EQ settings but this is not how I like to roll.

I don't mind digging into them to replace parts on the crossover PCB's but I need to know what's going to help and what's wasting time. I've already wasted enough time on these.

Thanks guys.

Edit: I should add that it's not possible to just bypass the crossovers and bi-amp as we don't have the amp channels and NL4 and buying such would be more expensive then just selling them off for something else.