In all honesty, even the test bench DMM did a poor job of measuring driver and resistor resistances. Not really sure as to why. At any rate, I found them both to be hovering around 5.1 ohms, which is closer to reality, I’d hope. This was done at about half a volt for the entire circuit. Similar results were found at 1 volt.

I still need to figure out what is wrong with my free air impedance measurements.

Max,

Driver build specifications can "evolve", as I mentioned, the spec sheet for the B&C 12NDL76 shows a Re of 5.1, exactly what you measured. Small changes in resistance in test leads and connections can make testing low resistance values frustrating- you'd not think much about an ohm or three measuring 600 ohms, but even a quarter ohm seems like a lot measuring around a 5.1 Re.

The 2 Hz or so difference you measured in the resonant frequency between the two drivers may be within typical tolerances. However, being around 8 Hz high seems fishy- try a simple "reality check", and measure the Fs the "old fashioned way".

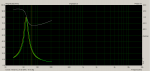

To measure a driver’s resonant frequency, connect the “+” output of a frequency generator/amplifier output directly to the driver “+”, place a 10 ohm (or so) resistor in series with the “-“ to the driver “-“ . Connect an AC voltmeter across the resistor leads. Adjust the frequency up and down until the voltage across the resistor reaches it’s minimum. The voltage minima is the resonant frequency.

I just performed that test on a brand new B&C 8NDL64-8 and measured the Fs at 87 Hz,

7 Hz higher than the spec sheet rating of 80 Hz.

Hmm, sound familiar?

I then “broke in” the speaker by pushing the cone in and out by hand to around Xlim (as far as the suspension would allow) several times, then repeated the test, the

Fs dropped to 78 Hz !

I had used around 4V for the two initial tests, after a few minutes decided to try 1V (”small signal”) and read around 82 Hz, 4 Hz higher..

Bringing the voltage back up to 4V, the Fs dropped to 80Hz. The suspension probably is not fully broken in, and these stout little cones need a bit of juice to move.

At any rate, your 12NDL76 have an Xmax of 6.5MM, Xlim is likely around 13MM.

To “break in” the speaker without days of ridiculously loud use requires the suspension to be pushed a bit past Xmax, over 1/2” peak to peak. At a very low frequency, like 20 Hz, very little voltage is required to reach that excursion, far less than the speaker can handle safely.

By hand, you should be able to safely push those cones to around 1” peak to peak, if you have not, I suspect your speakers will read a lower Fs after.

If after "really" breaking in the speakers your Fs readings the "old fashioned way" don't agree with your new test gear, something's wrong with the new tester.

If that's the case, other than checking it's series resistor is within spec, no more suggestions ;^) ...

Art