B&C ME464

- Thread starter Helge A. Bentsen

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is the jury out yet concerning the differences in sound between the BMS and B&C coaxials?

Here's an update with 4x10 config. This looks better than the previous 4x12 config I showed previously. Black curve is for 4x Beyma 10MC700ND at 700W each, grey cure is with 4x B&C 10NW76 at 400W each (RMS ratings for those drivers). This is 40in tall x 22in deep x 23.5in wide at the front, 11in wide at the back. Weight estimate is 112 lbs or 51kg if using 15mm BB. Using Lite Ply and/or sandwich panels, this could possibly come down another 30 lbs or so.

Robert, just wondering if this plan ever went any further than here? It’s a great design. I have sourced the 464 horn and drivers. Now I’m looking for the best box design possible (ie a PM90 but with the 464).

Sent from my iPhone

Chris -Robert, just wondering if this plan ever went any further than here? It’s a great design. I have sourced the 464 horn and drivers. Now I’m looking for the best box design possible (ie a PM90 but with the 464).

Nope, that design hasn't gone anywhere since then. That was a fun exercise, but it's too large for my needs. @Nicco Cerve was going to have a go at it, but I'm not sure where he's at with that. I'd be happy to email you the geometry files if you'd like. Or could tweak the model if there's something you want to change. It's mostly sorta-kinda parametric, so it should be relatively easy to update.

I've got a pair of DCX464 and HF950, and I'll likely build a PM90-ish sorta thing. My projects typically have an embarrassingly long gestation period due to both time poverty and analysis paralysis.

- Robert

I may one day steal that as a band name..."...analysis paralysis.".

- Robert

Chris -

Nope, that design hasn't gone anywhere since then. That was a fun exercise, but it's too large for my needs. @Nicco Cerve was going to have a go at it, but I'm not sure where he's at with that. I'd be happy to email you the geometry files if you'd like. Or could tweak the model if there's something you want to change. It's mostly sorta-kinda parametric, so it should be relatively easy to update.

I've got a pair of DCX464 and HF950, and I'll likely build a PM90-ish sorta thing. My projects typically have an embarrassingly long gestation period due to both time poverty and analysis paralysis.

- Robert

Robert Thanks. I would be interested in seeing those drawings. I don’t personally have the talent to turn them into actual plans and measurements to make sawdust from but I’m sure I could find someone. The design looks very promising and exactly what I was looking for, a big PM464!

Sent from my iPhone

I don't have drawings, just 3D CAD at the moment. Would you have the pieces CNC cut? Or would you use normal human tools? I'll go back and have another look and see what it would take to make some drawings. All I ask is you call it a RL464Robert Thanks. I would be interested in seeing those drawings. I don’t personally have the talent to turn them into actual plans and measurements to make sawdust from but I’m sure I could find someone. The design looks very promising and exactly what I was looking for, a big PM464!

What drivers were you going to use?

I don't have drawings, just 3D CAD at the moment. Would you have the pieces CNC cut? Or would you use normal human tools? I'll go back and have another look and see what it would take to make some drawings. All I ask is you call it a RL464.

What drivers were you going to use?

For that definitely a CNC. And yes, indeed that will be the RL series of premium mid/hi!

Thanks Robert

I Was considering the 10NW76 or 10ndl64.

Sent from my iPhone

Hello,Chris -

Nope, that design hasn't gone anywhere since then. That was a fun exercise, but it's too large for my needs. @Nicco Cerve was going to have a go at it, but I'm not sure where he's at with that. I'd be happy to email you the geometry files if you'd like. Or could tweak the model if there's something you want to change. It's mostly sorta-kinda parametric, so it should be relatively easy to update.

I've got a pair of DCX464 and HF950, and I'll likely build a PM90-ish sorta thing. My projects typically have an embarrassingly long gestation period due to both time poverty and analysis paralysis.

- Robert

Sorry i just saw the recent developments.

I'm currently working on @Robert Lawson's model.

I'm modeling it as a single horn sealed back cabinet, instead of 4 parallel woofers in a vented enclosure.

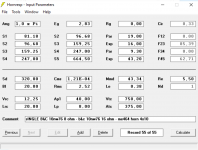

So i changed Ap and LPT to Ap1 and Lp and divided all volumes by 4, while switching to 1pi.

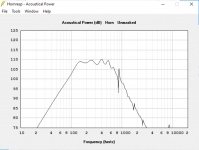

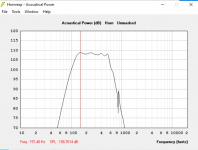

The horn design itself is good to me, with filtering and eq it has quite good response up to 400-450 hz, which is where i plan to cross over to the DCX.

I have to need to cross over at 100 hz since i have a 2 way bass solution, but sealed back modeling clearly reduces the low frequency extension.

I just added the thoath adapter to extend response in the higher range.

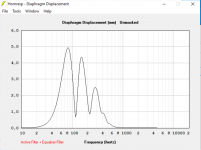

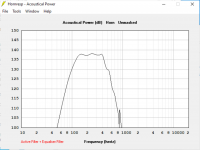

the 4th and 5th image are freq resp and displacement at 80V input for the single driver (800W).

Xmax is 6,8 mm.

I have no idea how to implement the new throath adapter in a real life desing; I tested a bunch of different drivers and i ended up choosing the one Robert simmed, mainly because i live in Italy and i'm already using B&C products, so it's easy to get them.

I'm looking forward to import the 3d model on Akabak as soon as i have time to sort some thing out with the software, and build a protopype as soon as i sell out my old midtops.

I'm actually quite new to modeling, but hope to get better results soon

Attachments

Last edited:

Hello,

Sorry i just saw the recent developments.

I'm currently working on @Robert Lawson's model.

I'm modeling it as a single horn sealed back cabinet, instead of 4 parallel woofers in a vented enclosure.

So i changed Ap and LPT to Ap1 and Lp and divided all volumes by 4, while switching to 1pi.

The horn design itself is good to me, with filtering and eq it has quite good response up to 400-450 hz, which is where i plan to cross over to the DCX.

I have to need to cross over at 100 hz since i have a 2 way bass solution, but sealed back modeling clearly reduces the low frequency extension.

I just added the thoath adapter to extend response in the higher range.

the 4th and 5th image are freq resp and displacement at 80V input for the single driver (800W).

Xmax is 6,8 mm.

I have no idea how to implement the new throath adapter in a real life desing; I tested a bunch of different drivers and i ended up choosing the one Robert simmed, mainly because i live in Italy and i'm already using B&C products, so it's easy to get them.

I'm looking forward to import the 3d model on Akabak as soon as i have time to sort some thing out with the software, and build a protopype as soon as i sell out my old midtops.

I'm actually quite new to modeling, but hope to get better results soon

Nick how are you making out with this??

I’m looking to have a box, similar to the PMs that gets the 100-400 range, 2 measly octaves, enough sensitivity and ultimately overall output capability to slightly exceed that of the 464, so that you can just maximize the output capability of the ME464/DCX464 which is about 107db overall and a total summed output of 380w 260/120 at 107db/w/2.83v.

That being said, you can get that out of 4 ordinary vented 10s (Pick a manufacturer that will give you 95db avg sensitivity per driver- 18S, B&C, Beyma, and Faital- and possibly a pair of 12s (probably a 12NDL88 tuned for 80) but definitely 4 12s (12NDL76 tuned 80). You could get that from a pair of 15s as well and just cut down the B&C full range box size and use a pair of 15NDL88s (possibly even the 76s don’t know about excursion limits there) tuned for 80hz, which will get you to about 100db sens at 2.83v and enough power capability to achieve the goal of a top end of 134db, just about equalling the coax total summed output. Ideally we want to overshoot that 134 by 3db or more hence using 4 vented 12s bringing us to 139db. You can use the 30degree vertical angle employed by B&C in their design to bring the centers closer to 1/4wv (more toward 1/2 in reality here) however swapping the 15s with side by side horizontally aligned 10s or 12s. The 12s can be angled inward toward the midline of the box as well to achieve the same overall width of the horn baffle which would add a slight bit of gain to the bandpass and the horizontal, appx 160mm. add 36mm for the side panels for an overall appx 200mm width. YYou can keep the 12s vertical as well which brings the center to center distances to the center of the ME464 the same as the 15 angled.

I’m going to attempt a prototype build of an MTM design, with 2-12” drivers above and below the ME464. They will be modular which will also enable me to do an MMT arrangement with the cube of 4 below the 464 and compare performance. The tune will be 80hz for a HP goal of 90-100hz.

If someone is pretty proficient with horn design you can try adapting the PM90 into a PM464 using the same horn dimensions for the midrange in a wider format cab to accommodate the 464 setup.

Robert and Nick your designs have some real potential however for me the cost of 4 Beyma 10s at 330$ USD each plus the pretty intense build complexity of that 4 horn design is somewhat cost prohibitive, when a pair of 12NDL76s as proven in the PM do the job just fine at 440$ USD and a much less complex build.

Anyway going to try the plain vented 4 driver design and see how it models, first with an MTM config.

Sent from my iPhone