Re: DIY mini-stage/riser/platform

I dont disagree with you at all and I even recommended reinforcing where the flanges are mounted. But the people above me didnt want to hear it. That being said the two decks we keep in house are used almost 7 days a week for 6 months now with zero issues. In fact weve gotten more compliments on them that I expected. If they were my own I would definitely make them more heavy duty. But sometimes ya got what ya got and as long as its not a real safety issue I make it work.

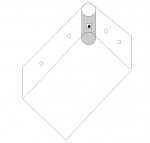

Here is a picture of the underside of the ones we build using the threaded pipes/flanges for support. Weve got 8 of them and they satisfy B level touring acts without and stability problems. They are also light enough for me to move and cary by myself.

Evan,

They may ''work'', but this is exactly the kind of engineering shortsightedness I was talking about. You need at least three cross members there(24'' O.C. if that's an 8' length of plywood, and I think it is). I'd prefer every 16'' O.C. for more rigidity. I'd also prefer using 2x6 lumber at least.

The flanges are mounted into the deck-the plywood is not meant to handle the shearing force that can be applied to this mounting scenario. If I were going to use the pipe flanges, I'd glue and screw another layer of plywood, triangular, 12'' on each side, in each corner that a flange goes. I'd then add a diagonally cut piece of the 2x4, sized to lay against the edge of the triangular plywood piece, and glue and fasten it all.

Then I'd use carriage bolts coming down from the top of the deck and bolt each flange to the now double thick reinforced deck corner.

Best regards,

John

I dont disagree with you at all and I even recommended reinforcing where the flanges are mounted. But the people above me didnt want to hear it. That being said the two decks we keep in house are used almost 7 days a week for 6 months now with zero issues. In fact weve gotten more compliments on them that I expected. If they were my own I would definitely make them more heavy duty. But sometimes ya got what ya got and as long as its not a real safety issue I make it work.