hey guys, I need some advices/ help on my next project, a subwoofer for a compact PA-Setup.

This setup is meant for DJ-Monitoring and small gigs, where really high SPL isn´t required.

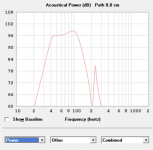

The Top is not finished, so no measurements here, but it uses a Mundorf AMT and a Beyma 10MC700ND in a closed box (maybe this will be changed to BR, as I have not that much experience on how much SPL is really required, and the Beyma in the closed box will be limited to max 115dB if crossed over at 100-120Hz, acc. to my poor Hornresp skills)

So now to the sub requirements, from most-important to least:

-sound quality (I use a ~400€ AMT and a 200€ Midbass driver-hopefully in a CB, so I also want the sub to be precise, fast, and so on, you know what what I mean)

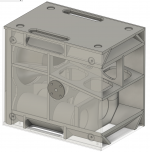

-compact design, MAX. 150L, better 120-130L

-of course high SPL and good low end but I don´t know what is possible here. I think 40Hz and 125dB would be nice to have, but the two points before are more important

What´s not (so) relevant:

-The driver... everything from 12"-18" is possible, if it can meet the requirements (300-400€ max. are OK if they are worth it)

Multiple enclosures are possible, the price range is planned for two of them, so it´s more like 600-800€, maybe 4 cheaper 12" will do it better than 2x15"?

-complicated build- I have a carpenter and a CNC router on my side

-Amp-Power, there is a LabGruppen FP10000Q waiting to get used (although this might change, as the subs will get an own amp-module maybe)

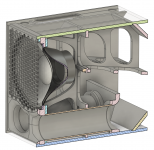

I started with 12" 6th order BP Designs from B&C and 18sound, but they both didn´t seem good enough, so I tried to re-design them... but I don´t want to built X prototypes, and I know enough about Speaker Design to not think that I can one-shot a perfect BP- design from a "good" Hornresp sim.

Then I came to 15" BR enclosures, the drivers are not that more expansive, and the output from 40-100Hz is compareable.

The Drivers I tried the 12" BP system:

Beyma 12P1000ND

12" BR-design:

B&C 12NW100

Oberton 12NSW600

Drivers for 15"BR:

B&C 15SW100ND/ 15SW115ND

Beyma 15LEX1000/ 15LEX1600

Oberton 15NSW600

Actually there are so many possibilities that I have lost the track many times, so some some advices/ hints for any good directions are very welcomed.

It´s also not that I really WANT to design my own sub (not yet) so if anyone knows, or would share a good design with me, please let me know.

I hope some of you can help me out here

This setup is meant for DJ-Monitoring and small gigs, where really high SPL isn´t required.

The Top is not finished, so no measurements here, but it uses a Mundorf AMT and a Beyma 10MC700ND in a closed box (maybe this will be changed to BR, as I have not that much experience on how much SPL is really required, and the Beyma in the closed box will be limited to max 115dB if crossed over at 100-120Hz, acc. to my poor Hornresp skills)

So now to the sub requirements, from most-important to least:

-sound quality (I use a ~400€ AMT and a 200€ Midbass driver-hopefully in a CB, so I also want the sub to be precise, fast, and so on, you know what what I mean)

-compact design, MAX. 150L, better 120-130L

-of course high SPL and good low end but I don´t know what is possible here. I think 40Hz and 125dB would be nice to have, but the two points before are more important

What´s not (so) relevant:

-The driver... everything from 12"-18" is possible, if it can meet the requirements (300-400€ max. are OK if they are worth it)

Multiple enclosures are possible, the price range is planned for two of them, so it´s more like 600-800€, maybe 4 cheaper 12" will do it better than 2x15"?

-complicated build- I have a carpenter and a CNC router on my side

-Amp-Power, there is a LabGruppen FP10000Q waiting to get used (although this might change, as the subs will get an own amp-module maybe)

I started with 12" 6th order BP Designs from B&C and 18sound, but they both didn´t seem good enough, so I tried to re-design them... but I don´t want to built X prototypes, and I know enough about Speaker Design to not think that I can one-shot a perfect BP- design from a "good" Hornresp sim.

Then I came to 15" BR enclosures, the drivers are not that more expansive, and the output from 40-100Hz is compareable.

The Drivers I tried the 12" BP system:

Beyma 12P1000ND

12" BR-design:

B&C 12NW100

Oberton 12NSW600

Drivers for 15"BR:

B&C 15SW100ND/ 15SW115ND

Beyma 15LEX1000/ 15LEX1600

Oberton 15NSW600

Actually there are so many possibilities that I have lost the track many times, so some some advices/ hints for any good directions are very welcomed.

It´s also not that I really WANT to design my own sub (not yet) so if anyone knows, or would share a good design with me, please let me know.

I hope some of you can help me out here