Re: Coaxial Wedge Collaboration

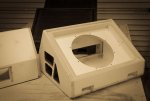

... I just converted the design to parametric CAD - Cubify design - and had another pair CNC'd from 16mm birch ply.....

I was asked in a PM about the design workflow.

- The 13 parts are designed in Cubify (a cut down version of Alibre which is now Geomagic). The parts include parameters for plywood thickness and drill hole sizes.

- I create an assembly in Cubify to check how all the parts fit together and alignment of holes.

- I create a 2nd assembly in Cubify with all the parts laid flat and spaced no closer than 15mm (0.6"). Behind the parts I place a part matching the size of a standard plywood sheet; 2400x1200mm (94.5" x 47.25"). The parts are laid out no closer than 20mm (0.8") from the edge of the plywood sheet part.

- I export a drawing (DWG file) of the flat view of the 2nd assembly.

- I import the DWG file into TurboCAD LTE and remove any lines not related to interior or exterior edges of the parts.

- For each part edge, I join all the lines into a continuous polyline. (This is important for the CNC software when it sets up cutting paths.)

- I move the part edge polylines onto layers: 1 layer for the plywood rectangle, 1 layer for interior part edges (line the loudspeaker driver hole or the handle cutouts), 1 layer for exterior or part-perimeter edges, and layers for each drill hole diameter. (Again this helps the CNC software with the order of cuts.)

- I then save the file in TurboCAD TCW format and send it to the CNC company.

Since the actual thickness of plywood is never accurate to it's rating, the CNC company sends me the (caliper) measured thickness and I update all the parts by setting the plywood thickness parameter then generate the drawing. Also, the 15mm and 20mm spacings were at the request of the CNC company.

I have all the CNC cuts done vertically (90 degrees) and some edge angles I cut later on the table saw. (The CNC company I use can cut some angles, but it complicates the setup and part spacing, especially for thick plywood.)

There are modules or plugins for Geomagic that enable going straight to CNC, but Geomagic, SolidWorks and the like are orders of magnitude more expensive than Cubify and TurboCAD.

I know CNC isn't in the spirit of this thread but it is becoming a lot more accessible.

Cheers,

Michael