Re: This winter's DIY-project just arrived.

This may help explain… http://www.powersoft-audio.com/en/docman/922-powersoft-bac-ipalmod-system-introduction/file

Perhaps Bennett can add something ...

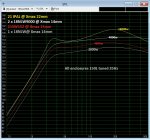

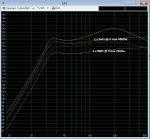

I don’t disagree with what the graph shows … In this case it's more complex and I assume there is good reason why the specifications state 99dB.Please take a look at the graphs and tell me where that 99db figure it taken from.

This may help explain… http://www.powersoft-audio.com/en/docman/922-powersoft-bac-ipalmod-system-introduction/file

Perhaps Bennett can add something ...