Re: No compromises front loaded double 18” cab

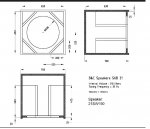

The numbers on B&C graph are for one box - Here is their original suggested design for the 21SW150

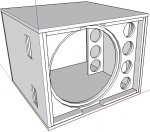

Forgive me if I'm missing something here, but you seem to have increased the port area quite a lot without any corresponding increase in length?

I'm sure there will be some extra effective length from having the ports built in along the box walls; will that be enough to keep the tuning the same do you think? If so, do you have any firm way of calculating that please? The closest I've seen seems to be more of a rough rule of thumb but I've yet to see anything more concrete. I'm not even sure how easily that rule of thumb could translate to triangular ports.

Many thanks,

David.

The numbers on B&C graph are for one box - Here is their original suggested design for the 21SW150