Hello all!

It took me a day to read this complete post! Great job to you all! Just to inform you guys i have just ordered before Covid-19 the B&C 12NLD76 with the idear they must be the mid drivers for my new cabinet. The cabinet design was not made yet but the idear was just make a point source with front loaded units. Till today!

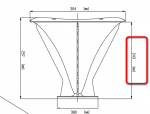

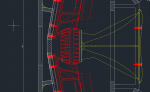

After reading the complete post now i will build my ow set of PM60 or PM90. The horn for the PM90 is at the moment in holland difficult to get. So probalby it will be the PM60 and this can be chanched afterwards to PM90.

I am for sure going to use the DCX464. I just love B&C speakers. They do what they promis till today for me. Only thing after reading the complete post is will they really fit? As i saw in a post Peter just put them loose in the box? Did you really build them in?

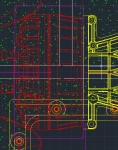

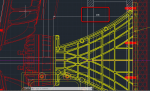

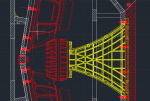

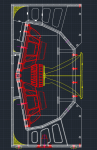

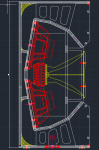

The only difference in the complete build will be the amp in the cabinet. Yes i know the weight. I have 2 Pascal x-pro-2 units with OEM dsp with FIR and a lot of other nice functions as lake also supports. I dont know if it will fit but i am going to try it. As base i will use the DWG drawing to check if it is possibol.

Maybe nice to know. the subs i have already are 2x SB18 a side. So crossing will be between 90 and 100hz from there.

It took me a day to read this complete post! Great job to you all! Just to inform you guys i have just ordered before Covid-19 the B&C 12NLD76 with the idear they must be the mid drivers for my new cabinet. The cabinet design was not made yet but the idear was just make a point source with front loaded units. Till today!

After reading the complete post now i will build my ow set of PM60 or PM90. The horn for the PM90 is at the moment in holland difficult to get. So probalby it will be the PM60 and this can be chanched afterwards to PM90.

I am for sure going to use the DCX464. I just love B&C speakers. They do what they promis till today for me. Only thing after reading the complete post is will they really fit? As i saw in a post Peter just put them loose in the box? Did you really build them in?

The only difference in the complete build will be the amp in the cabinet. Yes i know the weight. I have 2 Pascal x-pro-2 units with OEM dsp with FIR and a lot of other nice functions as lake also supports. I dont know if it will fit but i am going to try it. As base i will use the DWG drawing to check if it is possibol.

Maybe nice to know. the subs i have already are 2x SB18 a side. So crossing will be between 90 and 100hz from there.